In for a penny, in for a pound

Bambu Lab had a great sale during Black Friday. After months of fawning over their printers, I finally splurged on a Bambu Lab A1. I’m in love with it. I recently printed out a stand for my Nintendo Switch Pro Controller. It came out great! That said, it’s so light, it felt like it’d be really easy to knock over. Yesterday I re-printed it, but this time I included seven 20mm-wide cylindrical holes in the middle of it. During the printing process, just before the printer covered the top of these cylindrical holes, I paused the print, then filled these holes with pennies. Then I resumed the print. The result is the same object, but much heavier, so now it feels much sturdier.

I made those changes to the STL file using Tinkercad in a few minutes.

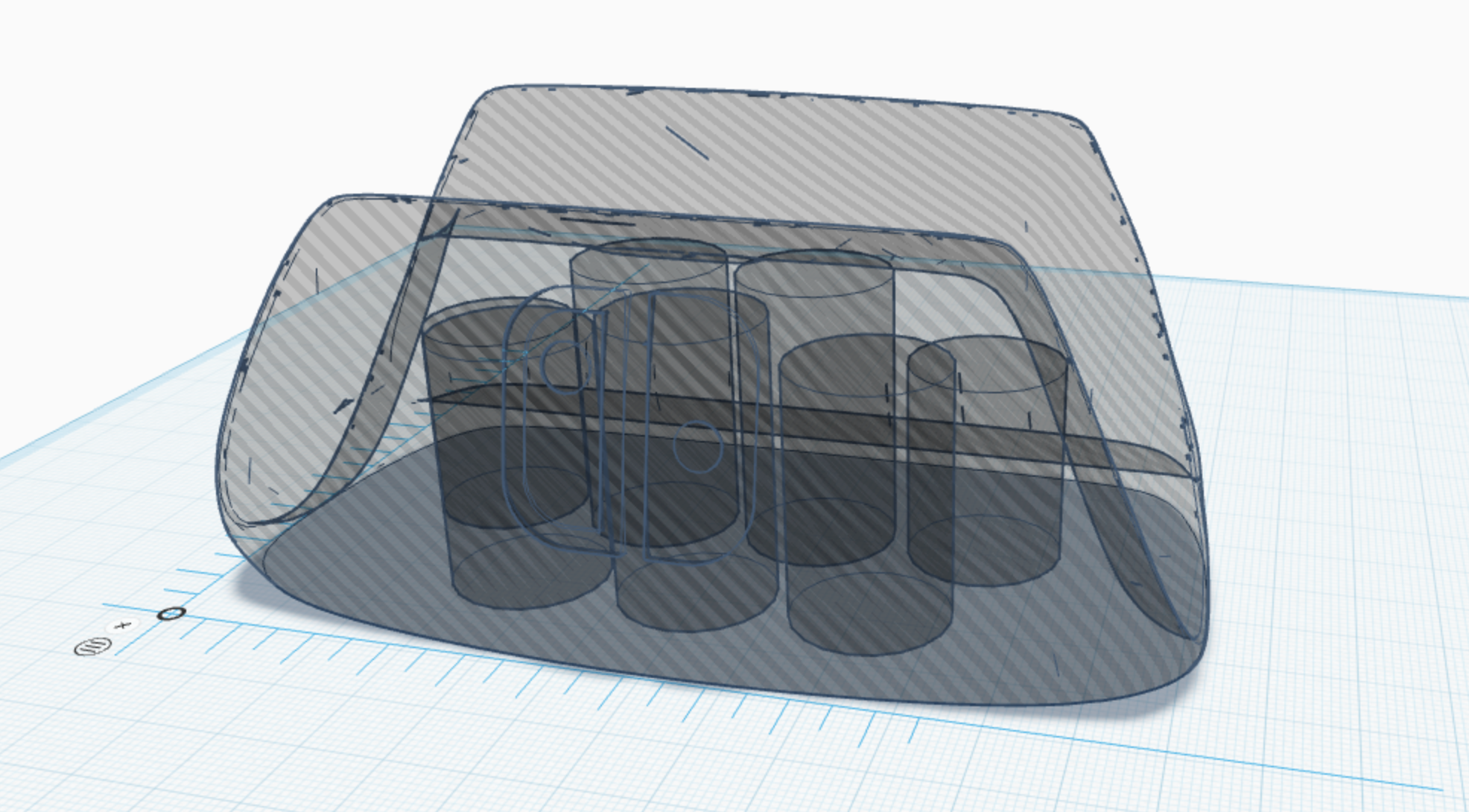

Here’s what that looks like in Tinkercad:

I exported that to an STL I imported into Bambu Studio.

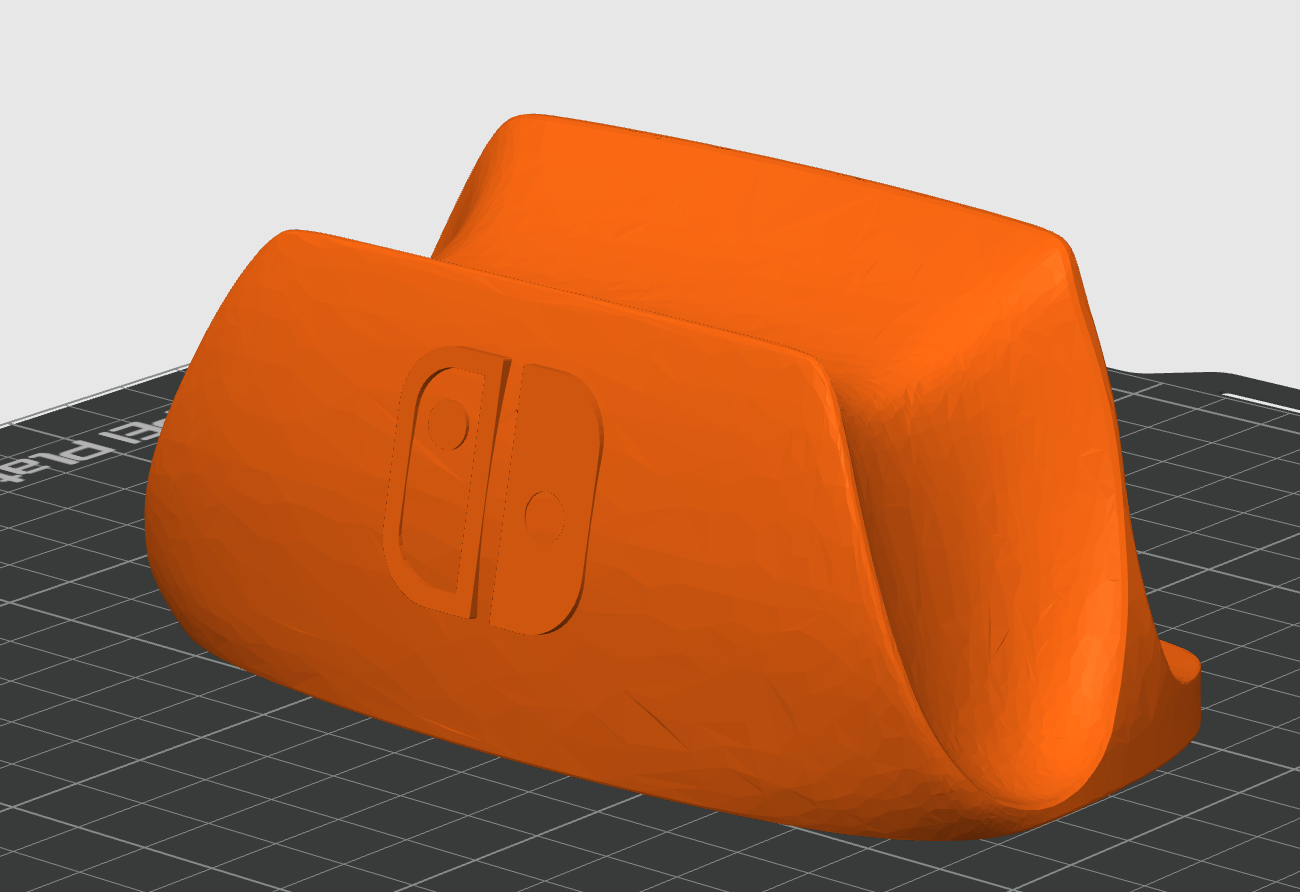

Sadly I forgot to take pictures of it while printing, but I did take pictures while printing a similar model for my Xbox Elite Controller. Here’s what it looks like with the print paused after I fill the channels with pennies.

I’m sure I’m not the first to think of using pennies to weigh down prints. I’ve heard of weighing down the interior of prints with sand, but that’s too messy! Knowing me I’d spill some and ruin my printer. In Canada pennies are no longer legal tender, so now I’m getting value from them again.